Features & Benefits

Why choose Touch Of Class Garages & Verandahs?

8 essential questions you should ask before ordering a shed:

- Does your building design meet Shed Safe accreditations?

- Has your building got site specific engineering and wind rating?

- Are you provided with a site-specific construction plan?

- Has your building been designed with Top Hat or Purlins?

- Are all major components marked for easy identification?

- Are your windows designed for a shed or a house?

- Are the brackets manufactured with high tensile 450+ Mpa steel?

- Your shed may be Australian made/manufactured BUT are the materials %100 Australian sourced?

Touch of Class Benefits

- ✓ Australian made, manufactured AND sourced materials.

- ✓ Family owned and run.

- ✓ Over two decades of building experience.

- ✓ Flexible structure designs.

- ✓ Class 10a -1a structures.

- ✓ Site specific engineering.

- ✓ Wind rated structures.

- ✓ Site specific DIY plans.

- ✓ Site specific Reg 126 (Permit document).

- ✓ Commercial and domestic designs.

- ✓ Heights up to 9 meters.

- ✓ Open spans up to 30 meters.

- ✓ Lengths in excess of 200m.

- ✓ Add on lean-to’s.

- ✓ Ability to change each bay length to suit your roller doors and requirements including intermediate wall placements.

- ✓ 10, 15, 22.5 and 30-degree pitch roofs.

- ✓ Easy DIY kits (Bolt together kits).

- ✓ BlueScope steel cladding 22 colours.

- ✓ Shed safe accredited.

- ✓ Delivery Australia wide.

- ✓ 15-year Scope -Steel warranty.

- ✓ Up to 20 structural warranties.

The Features

-

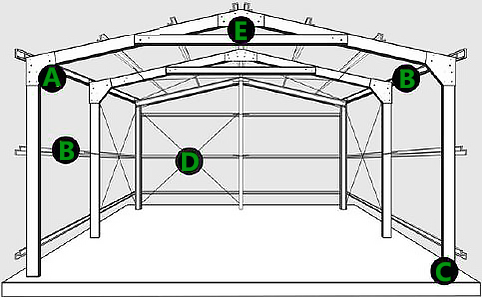

- A HAUNCH BRACKETS

* Designed to strengthen the

rafter-over-column joint to

prevent axial torque (Twisting)

* In larger buildings knee braces

are provided to strengthen the

haunch connection

- A HAUNCH BRACKETS

-

- B PURLINS & GIRTS

* 450 + mpa BlueScope steel

* Option of top hat or fully

bolted Z-purlins and girts

* Overlaps are 10% of bay width

plus an extra 100mm

adding significant strength

- B PURLINS & GIRTS

-

- C FOOTING FIXING

*A number of fixing methods

are available

- C FOOTING FIXING

-

- D BRACING

* Cross bracing and fly bracing

- D BRACING

-

- E APEX SYSTEM

* Apex brackets to full depth of

the rafter C-sections with full

width return flanges for

strength

* Apex brace (collar tie in tension)

is vital in the construction process

ad aids greatly in maintaining

structural integrity in high winds

- E APEX SYSTEM